Professional Chainsaw Repair Services

Serving Bowie & Surrounding Areas

Comprehensive Diagnostics And Repair

From No-Start To Power Loss, We Find The Cause

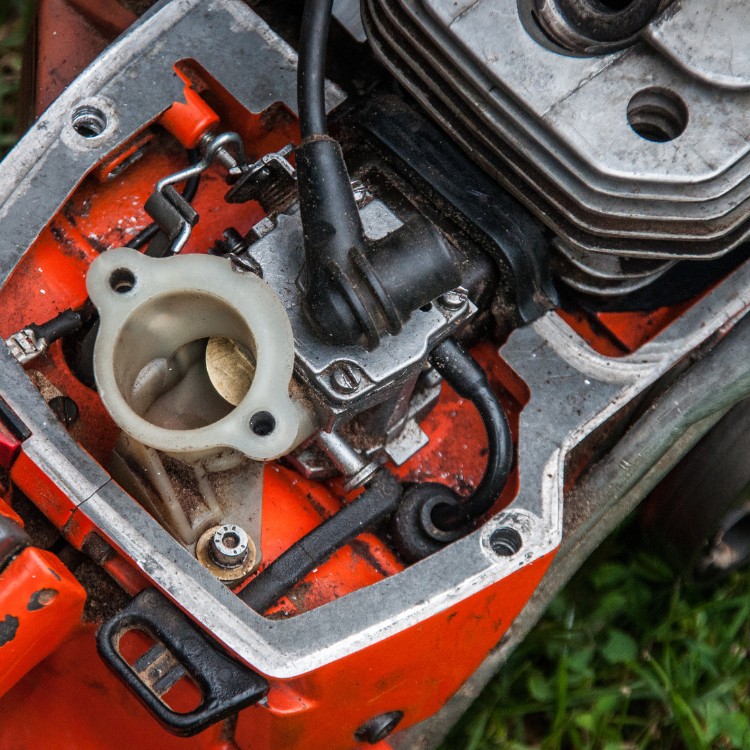

Every service begins with a thorough intake and multi-point inspection designed specifically for two-stroke chainsaws. We verify compression, check spark strength and ignition timing components, inspect the flywheel key, and examine the carburetor, fuel lines, primer bulb, and impulse line. We also perform crankcase pressure and vacuum testing to pinpoint air leaks at crank seals or gaskets, and we check exhaust flow and spark arrestor condition to rule out restriction-related power loss.

Once we identify the root cause, we perform precise repairs using proven procedures and quality parts. Typical services include carburetor ultrasonic cleaning and rebuilds (diaphragms, metering lever, gaskets), replacement of brittle fuel lines and filters, primer bulb and purge line service, ignition coil replacement and gap setup, recoil starter repair, clutch and rim sprocket renewal, chain brake band replacement, oil pump service, and crank seal installation. All repairs are test-run, fine-tuned, and verified under load before returning your saw.

Accurate Repairs Backed By Experience

We resolve hard-starting, flooding, and bogging that often stem from stale fuel, clogged metering circuits, misadjusted H and L needles, or air leaks. We correct chain no-oil conditions due to blocked bar oil ports or worn pumps, fix chain creep at idle by setting idle speed and addressing clutch issues, and eliminate loss of power under load caused by restricted mufflers, fouled spark arrestors, or low compression. Bar and chain problems such as rapid dulling, uneven cuts, blueing, and premature stretch are addressed by proper chain selection, sharpening, and bar rail dressing.

With 20+ years of experience, we service all major brands including Stihl, Husqvarna, Echo, Poulan, Jonsered, Makita/Dolmar, Craftsman, and more. We use OEM or premium aftermarket components as appropriate, set carburetors to manufacturer specifications, verify chain brake function and throttle interlock safety, and stand behind our work with clear communication and dependable results.

Extend Lifespan With Proper Care

Our sharpening service restores cutting performance with correct top-plate angles, consistent raker depth, and even tooth lengths. We advise on chain types (full chisel vs. semi-chisel, low-kickback options) for your wood and conditions. Bar maintenance includes dressing and deburring rails, cleaning oil passages, flipping the bar to even wear, and ensuring proper chain tension to reduce heat and extend component life.

Tune-up service typically includes a fresh spark plug, air filter cleaning or replacement, and a new in-tank fuel filter. We set carburetor mixture and idle for smooth acceleration without chain movement at idle. For fuel, we recommend a 50:1 high-quality two-stroke oil mix (JASO FD/ISO-L-EGD rated), fresh gasoline, and stabilizer. We also provide ethanol mitigation tips, seasonal storage procedures, and guidance on using non-ethanol fuel where available.

Safety is verified on every repair: chain brake engagement, throttle lockout, on/off switch, anti-vibration mounts, and fastener torque. We inspect cooling fins, flywheel, and muffler assemblies for debris and secure fitment, and ensure the spark arrestor is clean for safe operation. Before pickup, your saw is warmed, test-cut, and returned with recommendations for maintenance intervals and proper chain care.

Contact Us Today!

A member of our team will be in touch shortly.

Service Process, Pricing, And Scheduling

Clear Steps From Drop-Off To Pickup

Here is how our process works in Bowie: bring your saw in for a no-obligation evaluation, or contact us to arrange a convenient appointment time. We document symptoms, verify the model and serial, and perform a rapid initial assessment. Most diagnostic results are available quickly, and we communicate findings and options before any work begins so Bowie customers can make informed decisions.

Our pricing is straightforward in Bowie: we provide a written estimate detailing parts, labor, and any recommended maintenance. A diagnostic fee may be credited toward approved repairs. We prioritize OEM parts where required and select high-quality aftermarket components when appropriate to control costs without compromising reliability. Typical turnaround times are explained up front, and rush service may be available for urgent Bowie jobs.

Scheduling is simple in Bowie: reach out to kgsmallenginerepair to book your service slot, ask questions, or get a preliminary quote. We stand behind our repairs with clear communication, careful testing, and the expertise that comes from 20+ years of hands-on chainsaw service. Our goal is to keep Bowie homeowners, arborists, and landscapers cutting safely, efficiently, and with confidence.

Locally Owned, Family Owned

Rooted in your community.

Reliable

Dependable service you can trust.

Diagnosing $75

Affordable diagnostics, clear next steps.

Our Services